The definition and historical origin of Aluminum-Magnesium-Zinc plating

Definition: Aluminium-Magnesium-Zinc is a kind of alloy metal. it is mainly used for surface anti-corrosion treatment of steel and steel products.Initially pure zinc is used for the surface anti-corrosion treatment of steel products. With the improvement of technology, alloy metals such as Aluminum-Zinc alloy and Aluminum-Magnesium-Zinc alloy have appeared one after another, which increases the corrosion resistance of the metal layer.

Origin: it was originally developed and mass-produced by Japan's Nisshin steel corporation in the early 21st century. it is said that the purpose of development is to replace stainless steel in certain situation. Currently, it’s available in Jiuquan iron and Steel, tangshan iron and steel and Baosteel in China. With the industry upgrading, Aluminium-Magnesium-Zinc will be used more and more widely.

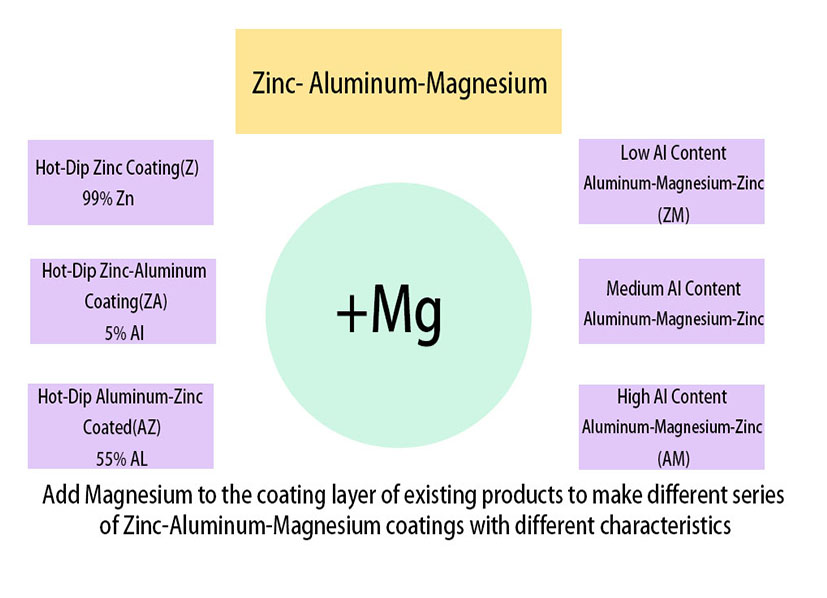

composition and classification of Aluminum-Magnesium-Zinc plating

Aluminum-Magnesium-Zinc-coated steel sheet refers to a coated steel sheet in which a certain amount of al and mg is added to the existing hot-dip galvanized coating or a certain amount of mg is added to the hot-dip Zinc-Aluminum coating. it has the characteristics of high corrosion resistance and high cutting edge protection performance.

china Baowu iron & steel group has summarized and analyzed commercial magnesium plating steel plates, and found that magnesium content in most coatings is less than or equal to 3%. according to the difference of aluminum content in the coatings, Aluminum-Magnesium-Zinc plating coatings can be divided into:

1. low al content Aluminum-Magnesium-Zinc coating. aluminum content: 1-3.5%. The coating is formed by adding a certain amount of Al,Mg and other elements on the basis of hot-dip galvanizing. china Baowu steel conducted its first industrial trial production in june 2016. The coated steel plate has also been tested by a color coating unit. And the color coated steel plate with low al content aluminum magnesium zinc substrate was developed successfully. The coating is an upgraded version of the corrosion resistance of the hot-dip pure zinc coating. china Baowu steel is referred to as BZM coated steel sheet and its color coated steel sheet.

2. medium al content Aluminum-Magnesium-Zinc coating, aluminum content: 5~11%

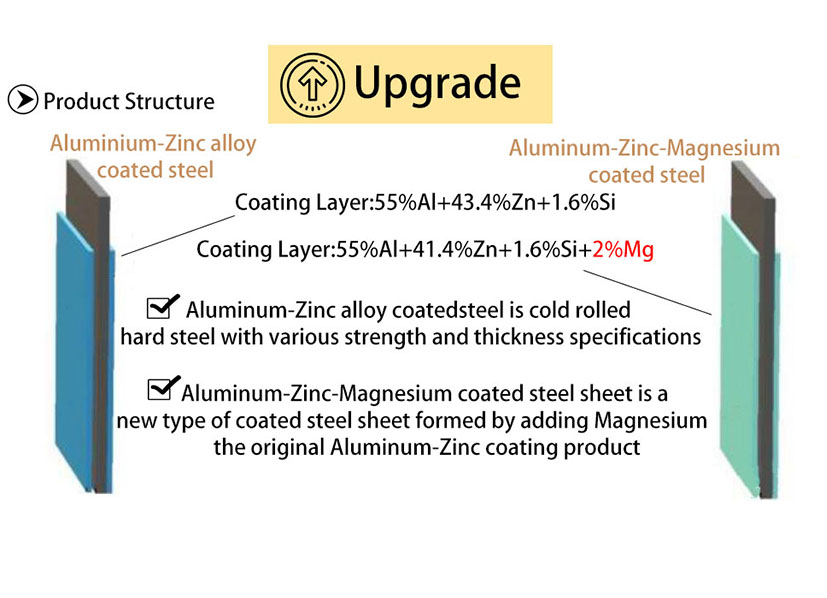

3. high al content Aluminum-Magnesium-Zinc coating, aluminum content: 55%.The coating is formed by adding a certain amount of mg and other elements on the basis of hot-dip Aluminum-Zinc. china Baowu steel conducted its first industrial trial production in august 2016. The coated steel plate has also been tested by a color coating unit. And the color coated steel plate with high al content aluminum magnesium zinc substrate was developed successfully. The coating is an upgraded version of the corrosion resistance of the hot-dip Aluminum-Zinc coating. china Baowu steel is referred to as bam coated steel sheet and its color coated steel sheet.

comparison between pure z inc, a luminum- z inc and a luminum- m agnesium- z inc

1. pure zinc coating, a metal coating with a zinc content of not less than 99%, is an economical anti-corrosion coating . i t is divided into spangle galvanized steel and no spangle galvanized steel, butthe corrosion resistance of the two is almost the same. If spraying or painting is needed in the future, the products without spangles will be more beautifu l. w hile the thick zinc layer products usually have spangle (for example, the weight of the zinc layer is 275g/m2 on both sides).

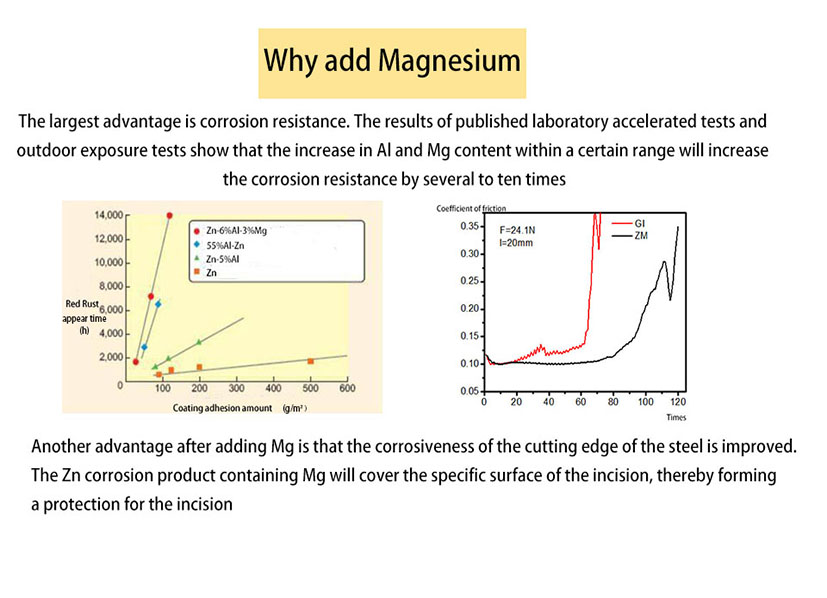

2. Aluminum-Zinc coating is a kind of alloy metal, in which the aluminum content is 55%, the zinc content is 43.5%, and the remaining component is silicon. Generally, the corrosion resistance of the Aluminum-Zinc coating is 2-6 times that of the same weight of pure zinc coating . The surface of galvanized steel coil can be modified by production technology to produce beautiful and uniform spangles, which can be directly used for building exterior or household appliances. However, there are some disadvantages of galvanizing. Firstly, the welding performance of galvanizing is not as good as that of pure Zinc. The welding process should be reduced as much as possible. Second, the cutting edge protection of aluminum zinc coating on steel plate is far less than that of pure zinc coating, and far less than that of Aluminum-Magnesium-Zinc plating.

3. The Aluminum-Magnesium-Zinc coating is an alloy metal with excellent comprehensive performance. The manufacturing cost is only slightly higher than that of the Aluminum-Zinc coating. The corrosion resistance of the coating is much higher than that of pure zinc and Aluminum-Zinc alloy. The protection performance is very good, and the welding performance is equivalent to that of pure zinc steel. at present, Aluminum-Magnesium-Zinc plated steel plate has been directly applied in the market. at the same time, the Aluminum-Magnesium-Zinc color-coated plate, which is used as a color substrate, is also achieved mass production and widely used by china Baowu iron & Steel. Aluminum-Magnesium-Zinc plating that can be used directly belongs to high al content Aluminum-Magnesium-Zinc coating. Aluminum-Magnesium-Zinc plating that used as a color substrate belongs to low al content Aluminum-Magnesium-Zinc. in the future, with the gradual increase in the requirements of construction and various industries for materials, Aluminum-Magnesium-Zinc-coated steel may gradually replace the application of Aluminum-Zinc steel and hot-dip galvanized steel in the market.

The alloy coating of the Aluminum-Magnesium-Zinc steel plate is a dense ternary eutectic structure formed by high-temperature solidification of Zinc, aluminum and Magnesium, so that a dense, super-coated layer that effectively prevents corrosion is formed on the surface of the steel plate.

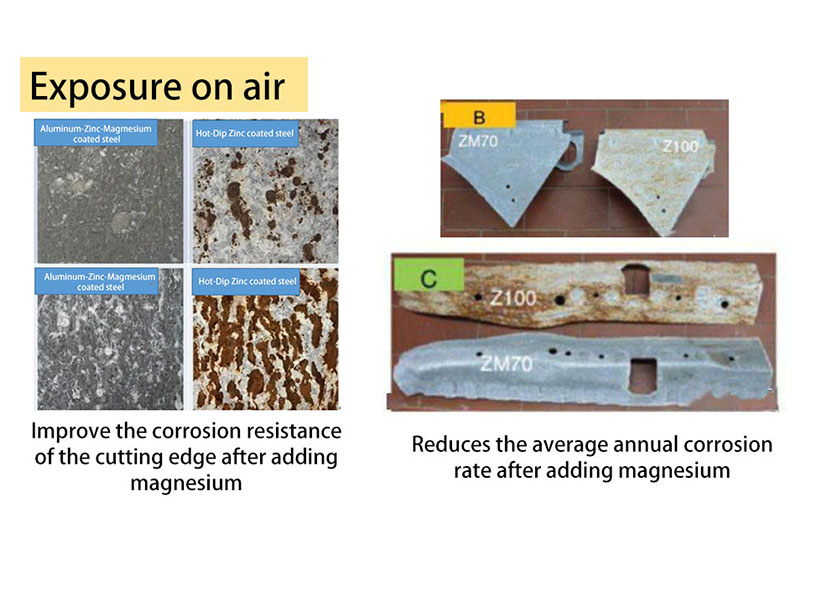

1. super corrosion resistance: in the case of the same coating, the corrosion resistance of Aluminum-Magnesium-Zinc plating is 10-20 times that of ordinary hot-dip galvanized steel.

2. wonderful self-repairing: With the passage of time, the cutting edge of Aluminum-Magnesium Zinc-plated steel will have the dissolution of the coating chemical composition and forming zinc Hydroxide, alkaline zinc Chloride, magnesium hydroxide and other compact protective film. The conductive property of the film is low and has obvious inhibition effect on corrosion of cutting edge.Therefore, Aluminum-Magnesium-Zinc-plated steel will repair itself in a short time after the initial surface rusts slightly, and will not rust again.

3. excellent processing performance and damage resistance: Because the Aluminum-Magnesium-Zinc coating is very dense and smooth, the surface hardness of the coating is 140~160HV, which is 2.5 times the hardness of ordinary galvanizing 55~65HV. This makes it have good stretching, stamping, bending, welding and other processing performance and excellent scratch resistance and wear resistance.

4. environmental protection: Aluminum-Magnesium-Zinc plating surface treatment does not contain three, six chromium and other heavy metal ions. It’s in line with the international environmental standards ROHS and is currently internationally recognized environmental protection products. it is very popular.in the field of environmental protection.

at present, the 275g/ ㎡ Aluminum-Magnesium-Zinc steel produced in china can achieve no red rust within 30 years under normal processing and use conditions. Therefore, this is a product far superior to galvanized steel and can be completely replaced the use of hot-dip galvanized products and some stainless steel.

as a professional photovoltaic bracket manufacturer in China, Corigy solar has a complete carbon steel and aluminum-magnesium-zinc production line with a monthly capacity of 100MW. OEM&ODM customers are welcome to inquire .

The company focuses on the development and production of high-quality PV brackets, and applies Aluminum-Magnesium-Zinc plating with the best corrosion resistance to solar power station projects.

With the mass production of Aluminum-Magnesium-Zinc products, they will be applied to more and more PV power stations in the future, providing better protection for the strength, weather resistance, and ease of installation of solar energy stations.

below are some photos of Corigy’s Aluminum-Magnesium-Zinc products.

contact Corigy solar and let us escort your new photovoltaic projects.